ValConnect for the IDC24 is a free software tool used to configure the IDC24-A(F) controllers sold by Val Controls.

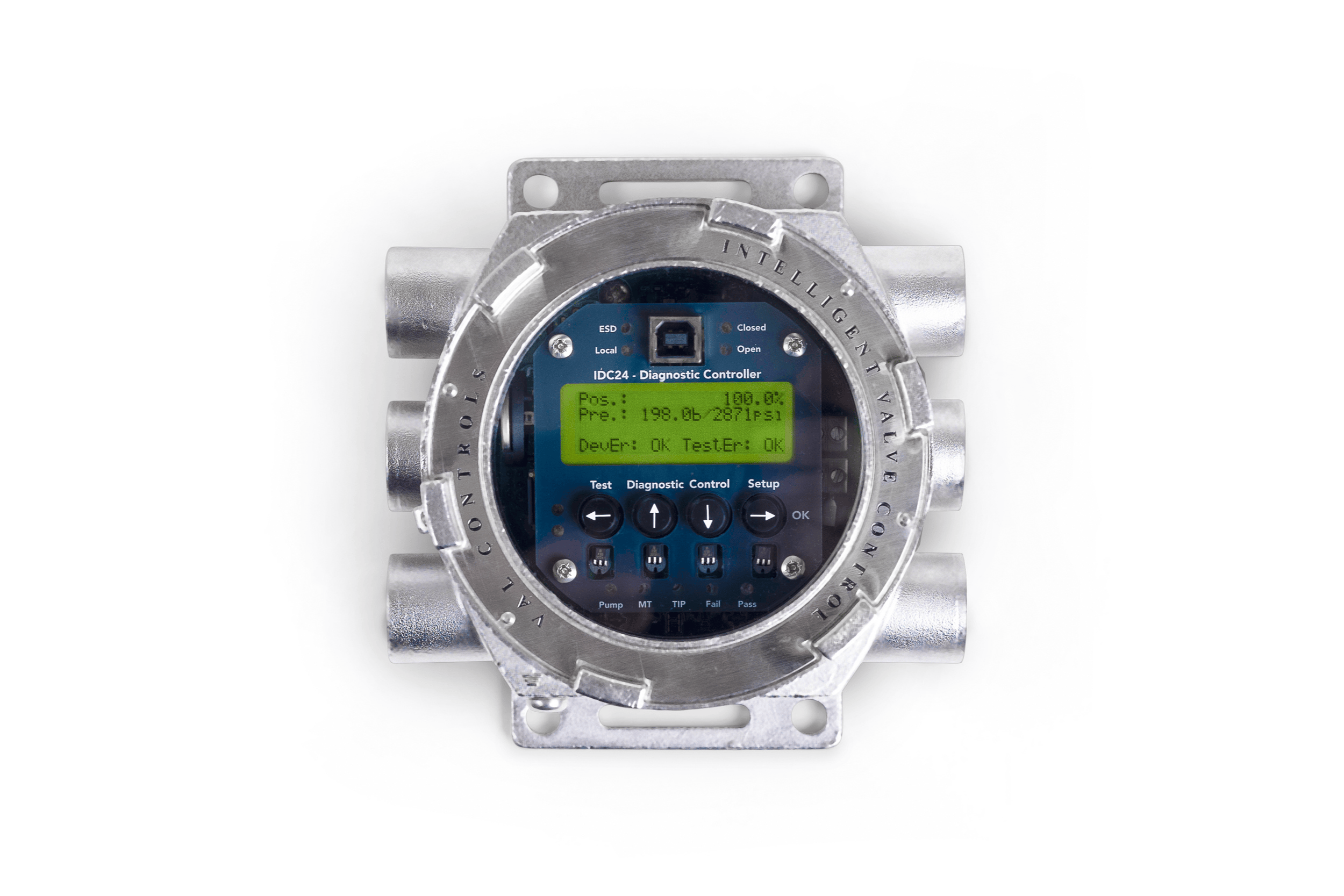

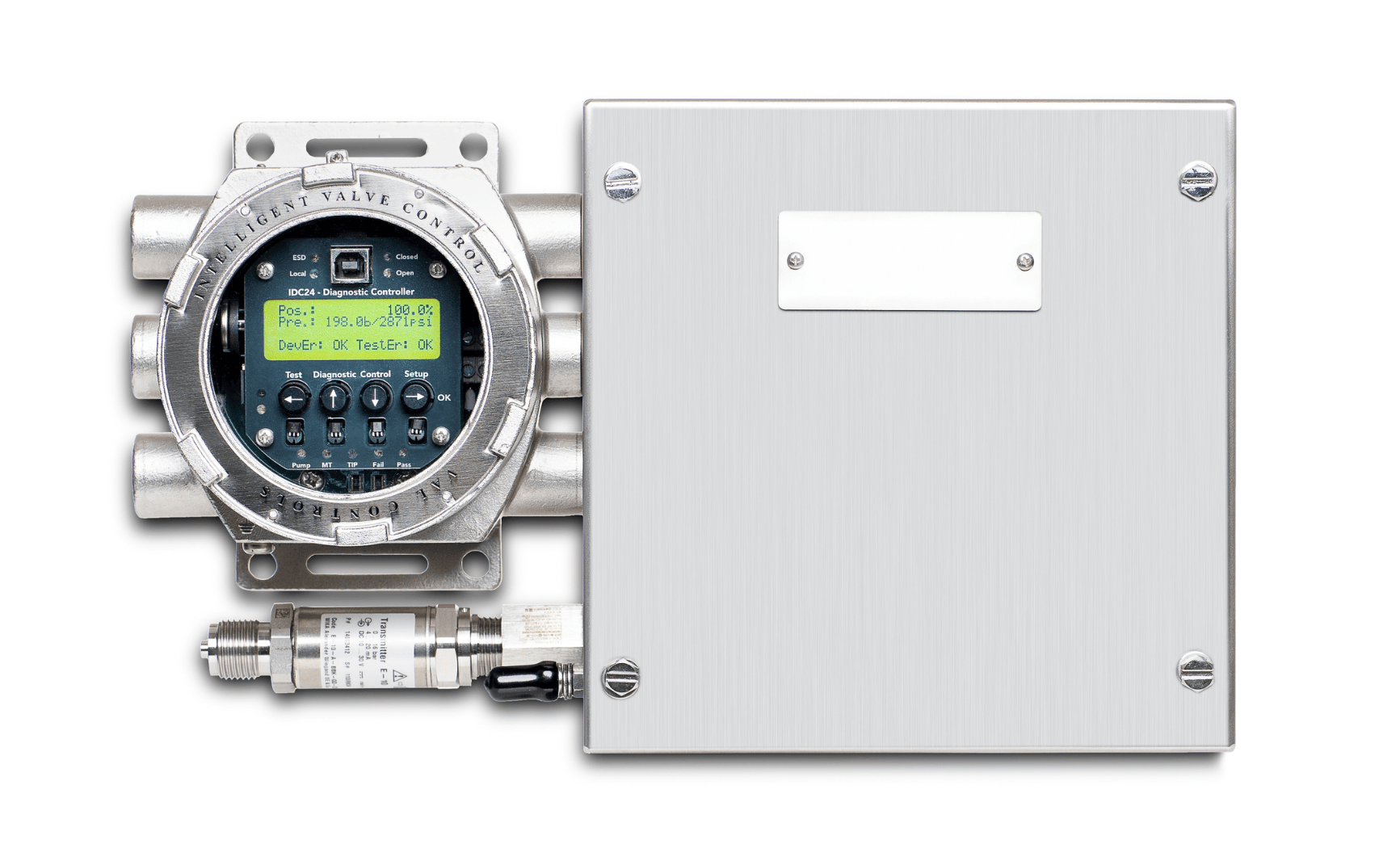

To configure the controller ValConnect must be downloaded to your PC and the PC connected to the USB-port located on the controllers local user interface.

With ValConnect it is possible to:

• Configure multiple units with the same configuration

• Save configuration for documentation

• Update software on the unit

• Monitor and control all in- and outputs