Emergency Shutdown Test - EST

What is an EST?

The monitoring of the ESD valves is done by the Intelligent Diagnostics Controller (IDC24) from Val Controls. Once a planned or unplanned shutdown occurs, data of the valves closing signature and time will be collected and stored in the controller.

It is important to collect these data points at both planned and unplanned shutdowns. At planned shutdowns the data can be used to perform a root cause analysis of the event and help find the cause of the unplanned shutdown. At planned shutdowns, the data collected by the controller is typically more reliable and efficient than manual testing of the closing time.

Furthermore, the data from all of the planned and unplanned shutdowns can be stored and compared to each other, to perform predictive maintenance and help the staff to better predict when certain parts need service or replacement.

Emergency Shutdown Test - EST

What is an EST?

The monitoring of the ESD valves is done by the Intelligent Diagnostics Controller (IDC24) from Val Controls. Once a planned or unplanned shutdown occurs, data of the valves closing signature and time will be collected and stored in the controller.

It is important to collect these data points at both planned and unplanned shutdowns. At planned shutdowns the data can be used to perform a root cause analysis of the event and help find the cause of the unplanned shutdown. At planned shutdowns, the data collected by the controller is typically more reliable and efficient than manual testing of the closing time.

Furthermore, the data from all of the planned and unplanned shutdowns can be stored and compared to each other, to perform predictive maintenance and help the staff to better predict when certain parts need service or replacement.

Emergency Shutdown Test

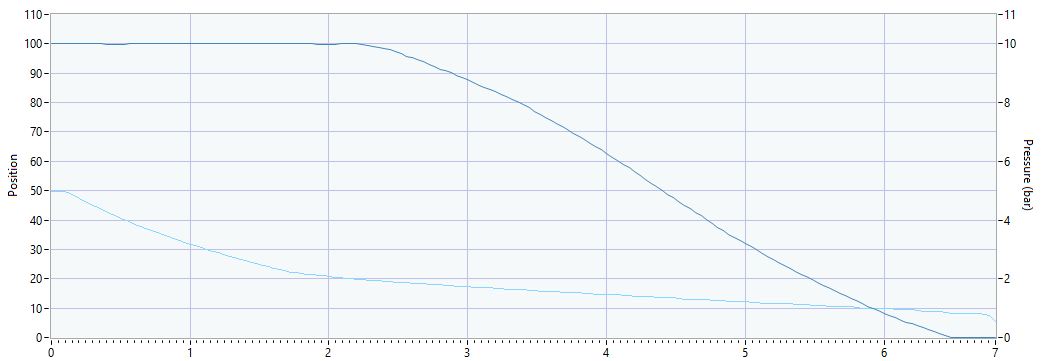

EST performed with full signature of position and pressure.

Benefits of Emergency Shutdown Test - EST

Safety

Better insight of why unplanned shutdowns on a specific site occur will ultimately decrease the number of unplanned shutdowns. Furthermore, the early detection of potentially faulty ESD valves will ensure that the Emergency shut down valves do work in case of an accident.

The testing of the valve closing time is typically done manually with a stopwatch etc. Manual time taking is prone to human errors. With the IDC24 controller the time taking will be done more precisely and reliably.

Data driven decisions

By monitoring the critical valves for a period of time, the end-user is able to do a root cause analysis of their operating failures and take the right actions in order to fix their operating failures. Without monitoring it can be challenging to identify the issues and communicate it to the rest of the organization.

The data driven approach to online monitoring of ESD valves will enable the staff to do predictive maintenance - replacing the right parts at the right time.

Production

With Val Controls intelligent diagnostics controller (IDC24) lots of valves can be tested at once which will reduce the overall time spent on ESD testing. At sites with a lot of ESD valves bottlenecks can ocour due to lack of personnel to test the valves, this issue will be eliminated aswell with the Emergency Shut Down Test.

Emergency Shutdown Test - EST

How the data is processed

Once a planned or unplanned shutdown happens, the data of the event will be logged and stored in the IDC24. The data can be stored in the IDC24 unit or shown in the control room where the event data can be analyzed and compared to previous data points.

Once an ESD capture happens, data of the event is stored in the IDC24 unit. performance data of the event itself will be collected as well as data from a preset period prior to the event.

The data can be transferred via. HART, Modbus, wirelessly or with USB which allows data of the event to be extracted locally or remotely. It is also possible to install a local control panel which will display an alarm in case of an event.

Data of the event can be analyzed where it is possible to see the exact time of the event, monitor the pressure and the valve closing performance. The data can be compared to previous events and testings.

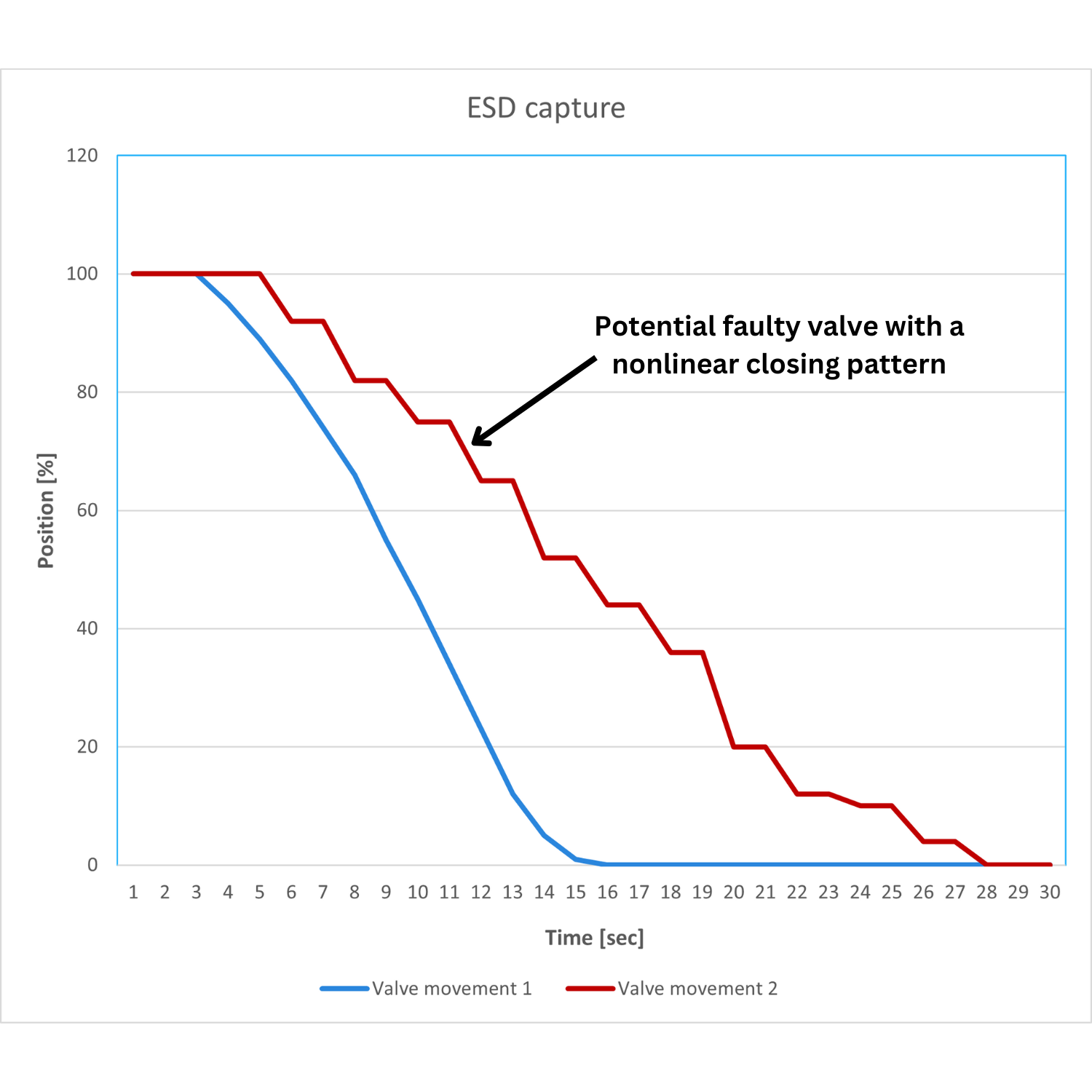

Valve closing analysis

In case of a planned or unplanned event, data from before and during the event will be stored in the Intelligent Diagnostics Controller (IDC24).

In this specific case data is compared to another similar valve (Valve movement 1) with a suspected faulty valve (Valve movement 2). It is discovered that valve no. 2 has a nonlinear closing pattern and is potentially faulty. This discovery led to further investigation of valve no. 2, and it was ultimately replaced at the next planned shutdown.

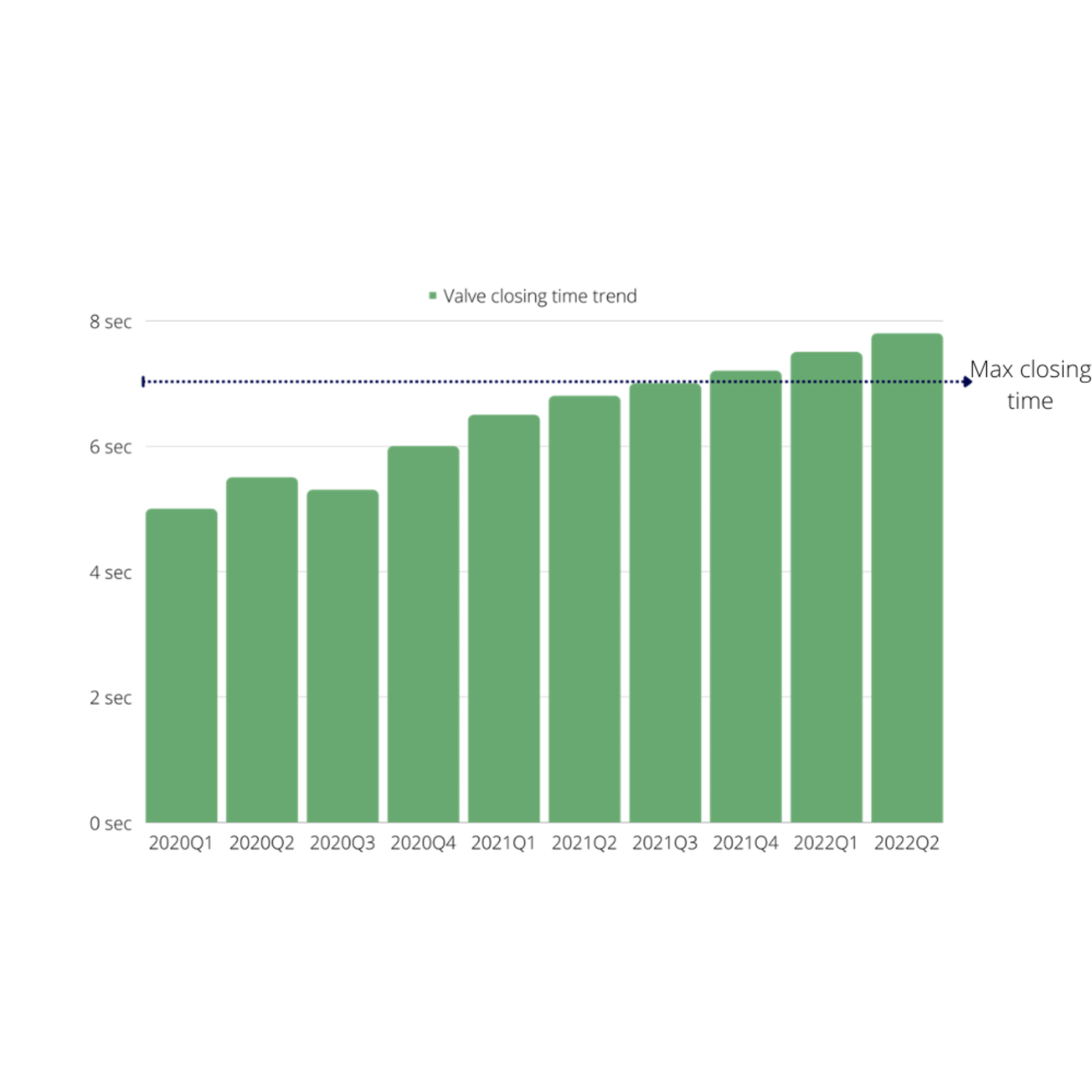

Valve trend analysis

Monitoring the valve closing time allows you to perform predictive maintenance and replace parts before an unplanned shutdown occurs. It is possible to break down the different actions during the valve closing, which offers insight in the following:

- SOV reaction time

- Breakaway time

- PST time

- PST pressure time

- PST return time

- Actuator fill time