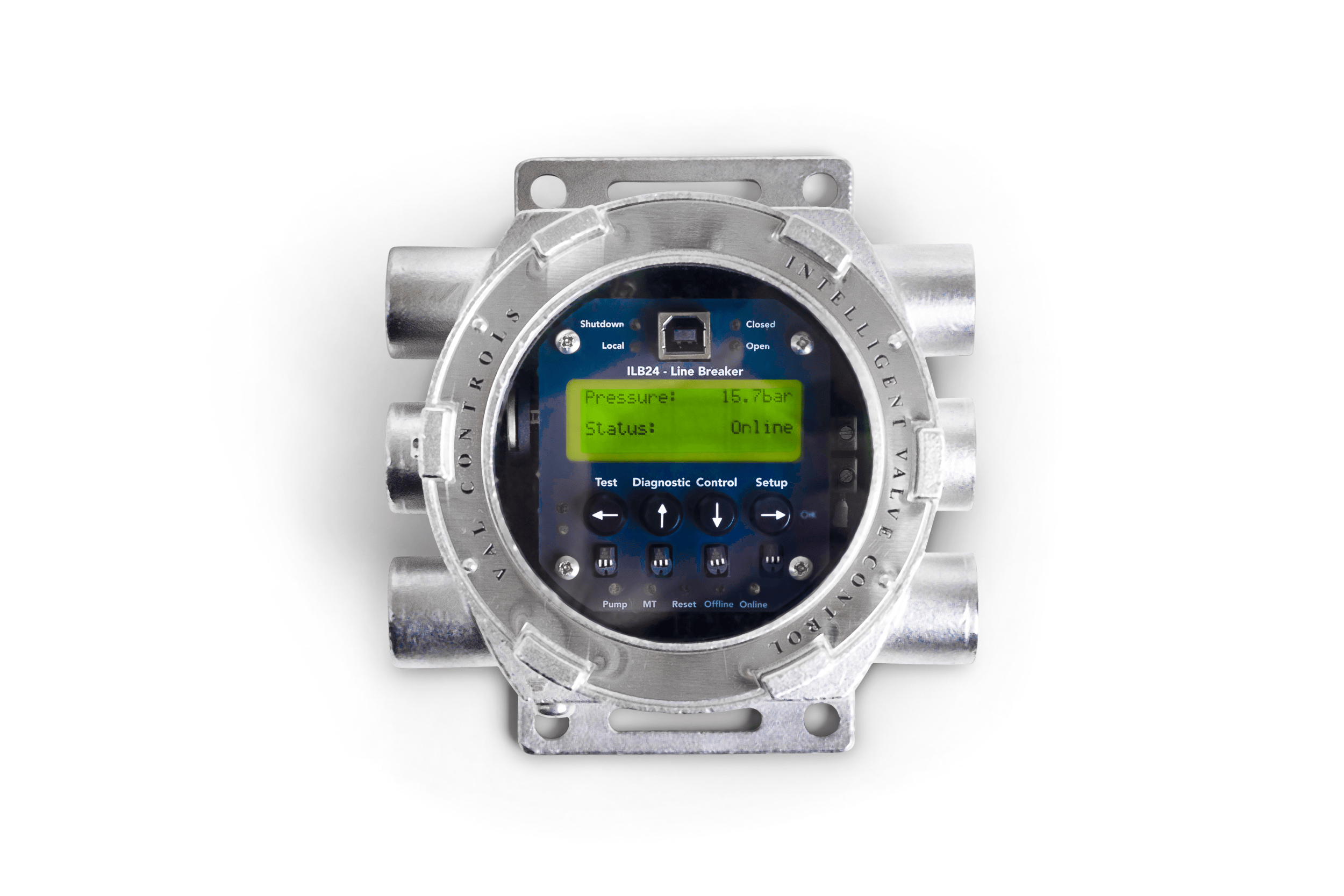

ILB24

Intelligent Line Breaker

Key product features

The ILB24 product range from Val Controls is a series of Intelligent Line Breakers used for pipeline monitoring and control. The ILB24 provides a straightforward solution to monitor and shut down the pipeline in case of an emergency. The Line Breaker constantly monitors the pipeline pressure and will shut down the flow if abnormal pressure is detected.

The ILB24 constantly monitors the downstream pressure of the pipeline and can be configured with a high- and low pressure limit. For each limit a major and minor pressure threshold can be set and if those are reached a predetermined action is performed.

The rate of drop is used to determine if a pipeline rupture has occurred. If the pressure drops at a preset rate (measured in bars per minute), a major or minor alarm is triggered, and an automatic shutdown of the pipeline can be conducted.

The rate of rise indicates a sudden increase in pipeline pressure. If the preset major and minor thresholds are reached, a major or minor alarm is triggered, and an automatic shutdown of the pipeline can be conducted.

The differential pressure shows the difference between the upstream and downstream pressure in the pipeline on each side of the valve. A pressure transmitter is placed to monitor the pressure on each side, which calculates

the pressure difference. If the predetermined threshold of the differential pressure is reached, a minor or major alarm is triggered, and an automatic shutdown of the pipeline can be conducted.

Movement alarm detects if the valve has not reached full open or closed within a defined time.

- Remote pipeline monitoring

- Internal memory up to 30 years data

- Advanced password protection with several levels

- Monitoring and logging software provided

- Generate reports for documentation

When configuring the ILB24 a minor and a major pressure threshold are set. If the minor pressure threshold is reached an alarm is displayed on the ILB24 and a message can be sent to the control room. A minor alarm will not trigger any automatic action and it is up to the operator for any onwards actions.

If a major pressure limit is reached the ILB24 can be configured to do an automatic shutdown of the pipeline. It is also possible to only display a major alarm message and not do any automatic actions.

Sensors needed

Each pipeline monitoring feature requires specific sensors to be placed at various points in the valve system.

The list below shows the sensors needed at the upstream pipeline, downstream pipeline, and valve position.

Sensor needed

Downstream pressure

Upstream pressure

Valve position

Low- and High-pressure

Yes

—

—

Rate of Drop - RoD

Yes

—

—

Rate of Rise - RoR

Yes

—

—

Differential pressure

Yes

Yes

—

Movement alarm

—

—

Yes

Partial stroke test

—

—

Yes

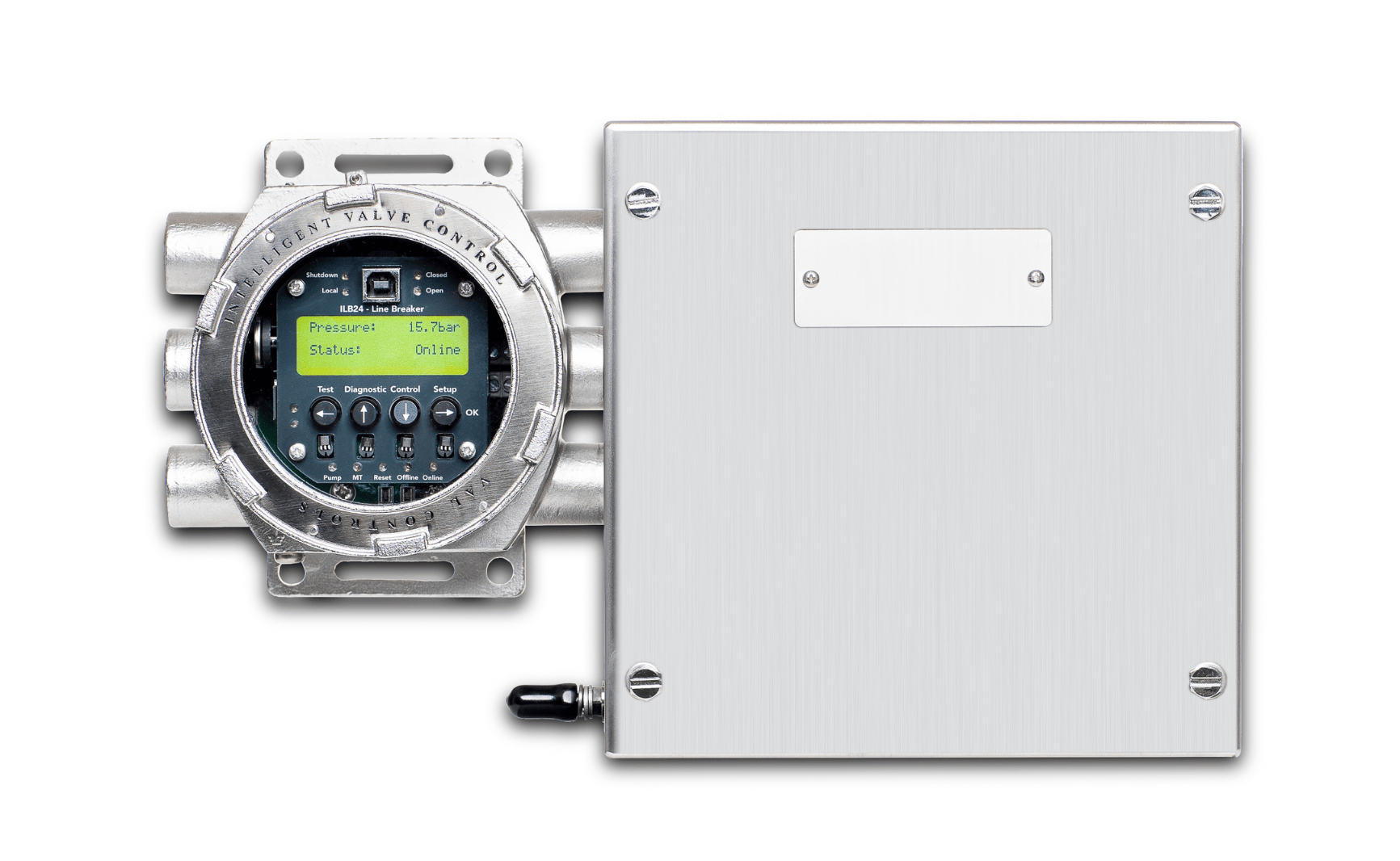

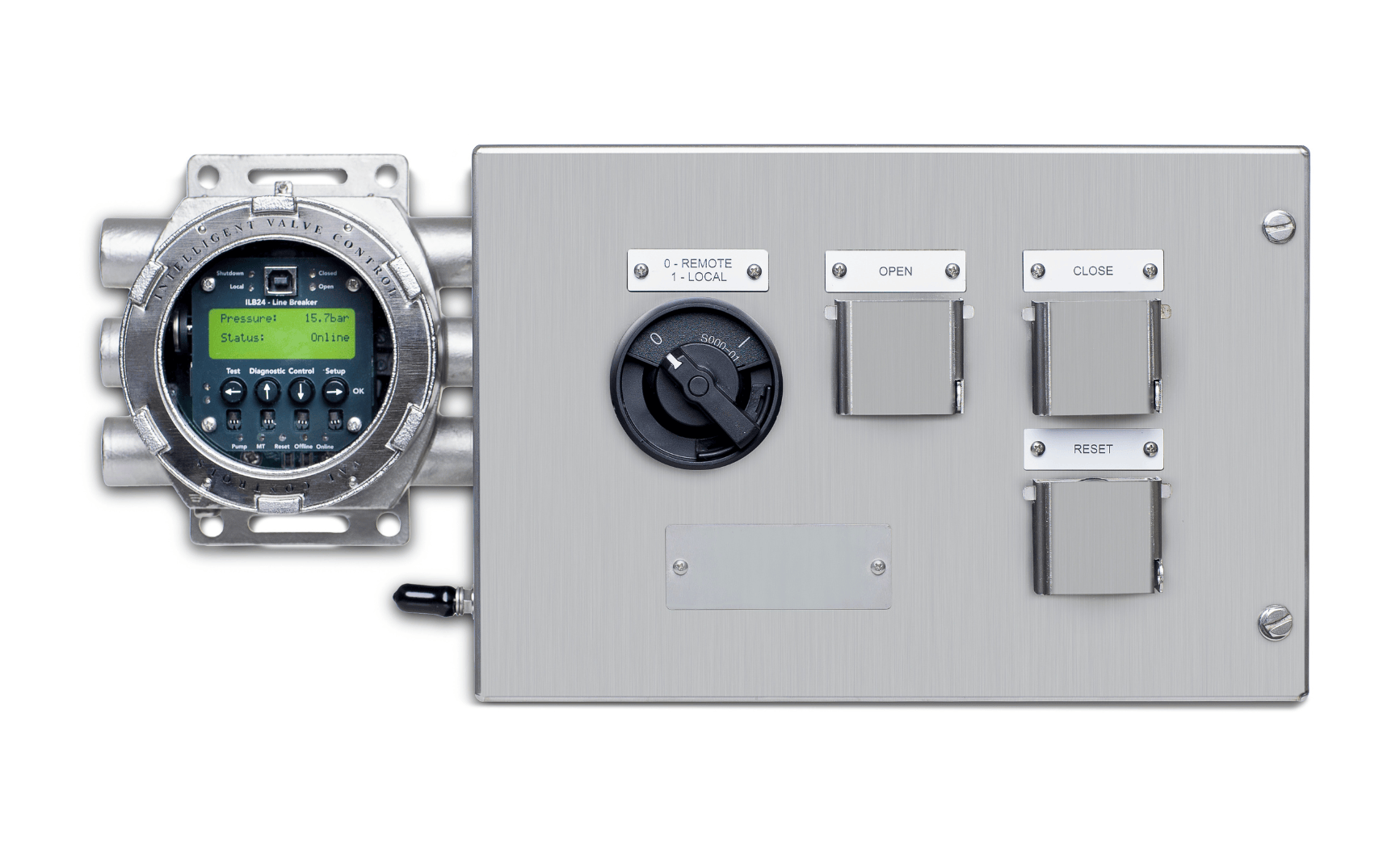

Control methods

ILB24 - Schematic example

Below an example of a system with a double acting actuator and two solenoid valves is provided. Please note that the ILB24 is compatible with most systems.

• SDV valves

• SR and DA actuators

• Hydraulic or pneumatic systems

• All solenoid valve brands

Line Breaker Control

Valve Control

Configuration software

ValConnect for the ILB24 is a free software tool used to configure all ILB24 controllers sold by Val Controls.

To configure the controller ValConnect must be downloaded to your PC and the PC connected to the USB-port located on the controllers local user interface.

With ValConnect it is possible to:

• Configure multiple units with the same configuration

• Save configuration for documentation

• Update software on the unit

• Monitor and control all in- and outputs

Case studies