Solenoid Operated Valve (SOV) Testing

What is Solenoid Operated Valve (SOV) testing?

The purpose of SOV testing is to exercise the ESD SOV without any movement of the complete valve system. Val Controls offers a solution that allows the plant to continue operating while the test is being conducted. The test results will be recorded in the controller and can be used to assess the performance of the ESD SOV.

Since the ESD SOV is a vital component of the safety instrumented system (SIS), which is designed to monitor hazardous conditions in a plant (operation unit) and respond in the event of a dangerous situation, it is essential that the SOV is functioning properly. Otherwise, the SIS will not work effectively.

Conducting the test will help to reduce the risk of valve stiction and potential malfunction by exercising the SOV.

Solenoid Operated Valve (SOV) Testing

What is Solenoid Operated Valve (SOV) testing?

The purpose of SOV testing is to exercise the ESD SOV without any movement of the complete valve system. Val Controls offers a solution that allows the plant to continue operating while the test is being conducted. The test results will be recorded in the controller and can be used to assess the performance of the ESD SOV.

Since the ESD SOV is a vital component of the safety instrumented system (SIS), which is designed to monitor hazardous conditions in a plant (operation unit) and respond in the event of a dangerous situation, it is essential that the SOV is functioning properly. Otherwise, the SIS will not work effectively.

Conducting the test will help to reduce the risk of valve stiction and potential malfunction by exercising the SOV.

SOV Testing for improved safety and maintenance

Val Controls provides a solution which can be used in any environment as well as existing or new installations.

The IDC24 controller is used for Solenoid Operated Valve testing and is compatible with:

- 1oo1, 1oo2 and 2oo2 safety instrumented systems

- ESD Solenoid Valves

- HIPPS Solenoid Valves

- Pneumatic and Hydraulic systems

The SOV testing can be performed as a stand-alone test or can be done in continuation of a Partial Stroke test.

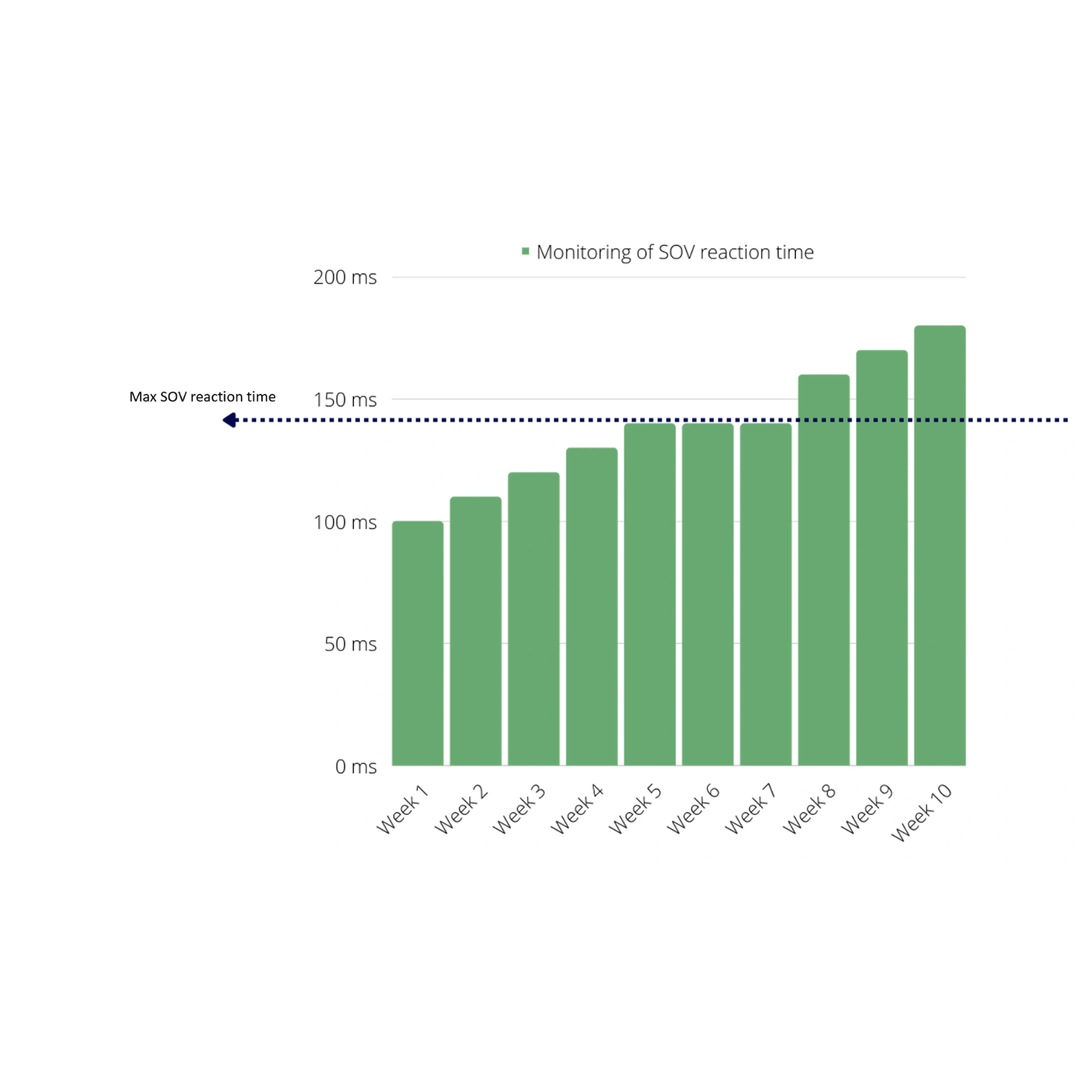

The software provided by Val Controls enables the end-user to monitor the SOV's reaction time, allowing them to predict when the SOV needs to be replaced. This predictive maintenance approach reduces the number of unplanned shutdowns and increases overall site safety.

Importance of testing Solenoid Valves in Safety Instrumented Systems

In many SIS applications, the solenoid valve stays energized and open during normal operation (note: this also applies to energize to trip applications). However, if the system detects an overpressure or other hazardous conditions, the valve moves to the closed position and activates the ESD valve to stop the process flow.

Despite the crucial role that the solenoid valve plays in maintaining the safety of the facility, equipment, and personnel, it is rarely used. In fact, it can remain in the same position for months or even years, increasing the risk that it will fail to close when needed. Testing and exercising the SOV frequently can help reduce the number of unplanned shutdowns and potentially dangerous failures, leading to improved safety and cost reduction.

Causes of Solenoid Valve Failure

In a typical solenoid-operated valve, O-rings create a seal by pressing against the chamber walls as the plunger moves. The plunger must first overcome the friction, or stiction, between the O-rings and walls to move. If the valve is inactive for a long time, the stiction may increase beyond its normal level, making it harder for the forces generated by the SOV coil to move the valve. Additionally, the presence of water or oil can leave a sticky residue inside the valve, further contributing to stiction.

Risk of stiction increases incrementally over time, infrequent testing raises the probability of valve failure on demand (PDF). Even without changing the architecture of the valving, more frequent testing will reduce stiction, lowering the average PFD. In addition to the potentially life-threatening safety concerns, including risk of fires or explosions, solenoid valve failure is a condition that has vast productivity implications - especially if it leads to plant shutdown.

Typical causes of failure

- Valve stiction

- Plunger stuck

- Blocked or restricted solenoid valve exhaust (or QEV)

- Sand/dust build-up, icing or insect nests

- Damage to instrument piping

- Supply pressure too high or low

- Slow reaction time

- Unknown expected lifetime of the SOV

Summary

Testing and exercising solenoid valves in safety instrumented systems is crucial for maintaining facility, equipment, and personnel safety. Val Controls offers a cost-efficient solution that can be used in any environment for existing or new installations. The IDC24 controller enables Solenoid Operated Valve testing and is compatible with 1oo1, 1oo2, and 2oo2 safety instrumented systems.

The software provided by Val Controls allows the end-user to monitor the SOV's reaction time, reducing the number of unplanned shutdowns and increasing overall site safety. By frequently testing the SOV, the risk of valve stiction and potential malfunction is reduced, preventing potentially life-threatening safety concerns and productivity implications.

Contact us for inquiries on how our SOV testing solution can benefit your facility.