IHP24

How does it work?

The IHP24 uses Solenoid Operated on/off Valves, SOV, to move the actuator to the requested set point. It has 4 or more outputs to control SOV’s depending on the model. The IHP24 is designed so it can use any solenoid valve on the market. The unit will automatically adapt the regulator to the performance of the complete system, during an automatic calibration. The desired position of the valve is sent to the IHP24 via the 4-20mA control loop or a communication protocol. The actual position is measured by the IHP via a potentiometer or a 4-20mA sensor. The set point and position signal is compared and the actuator is moved to the requested position.

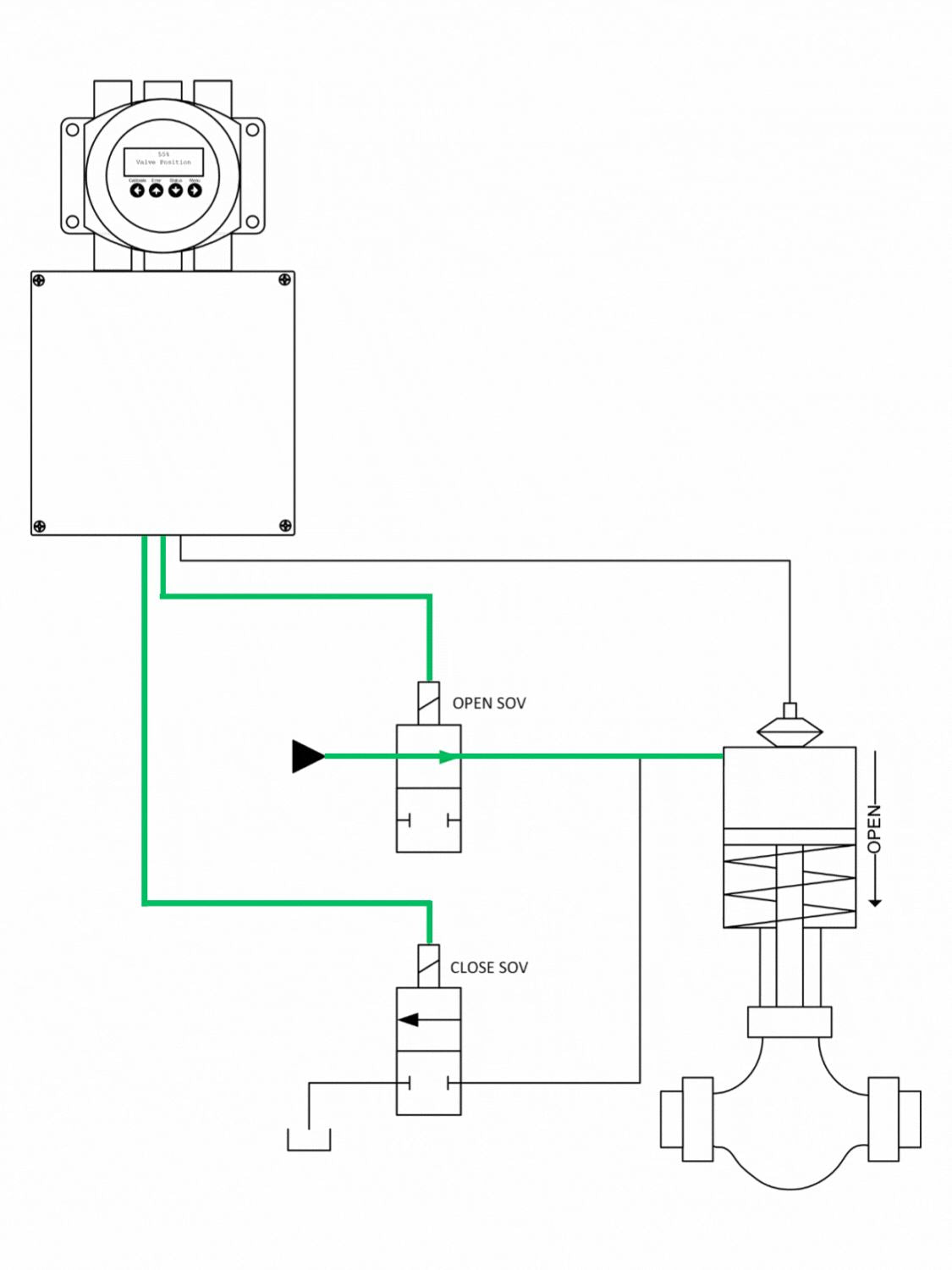

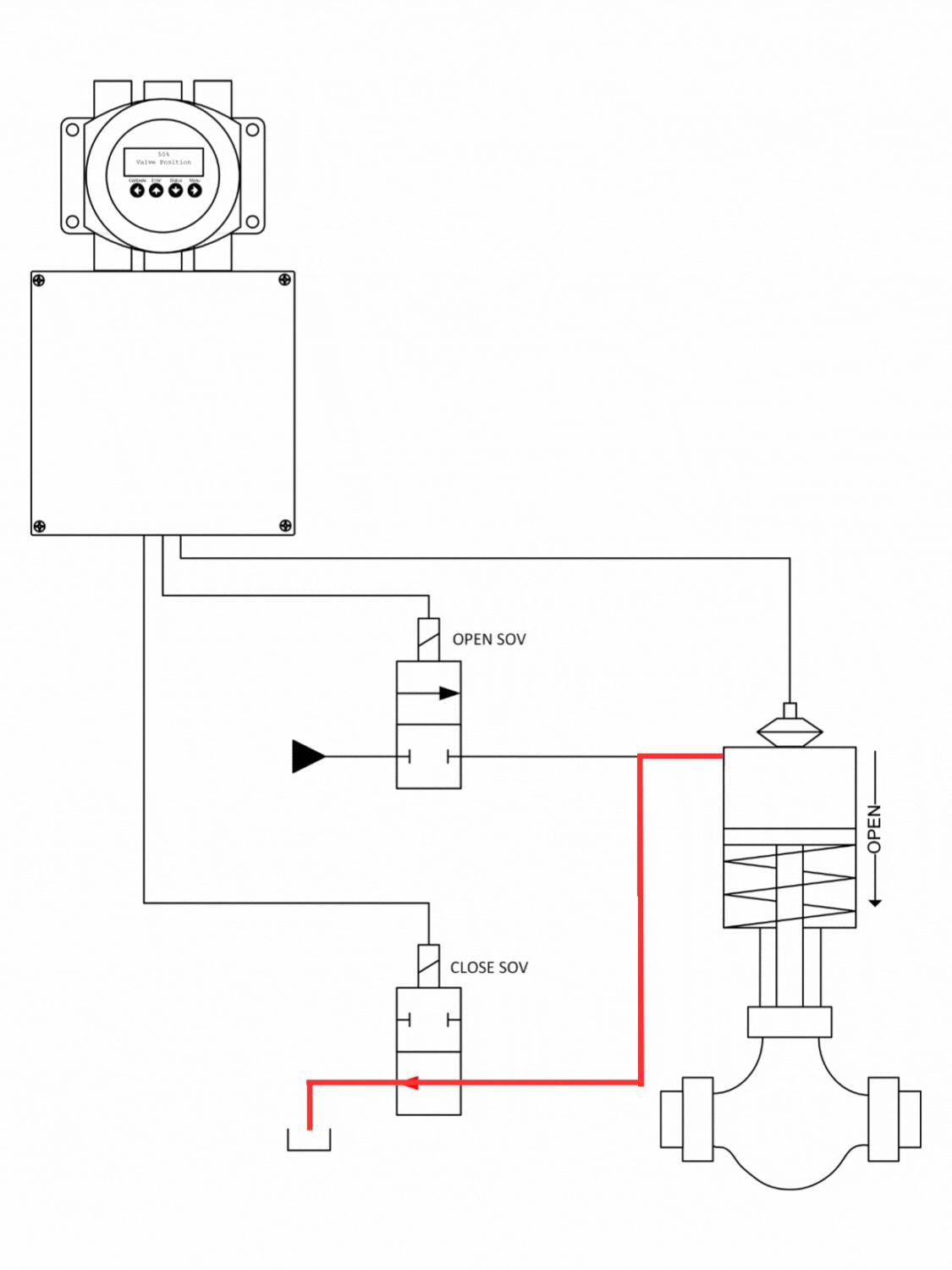

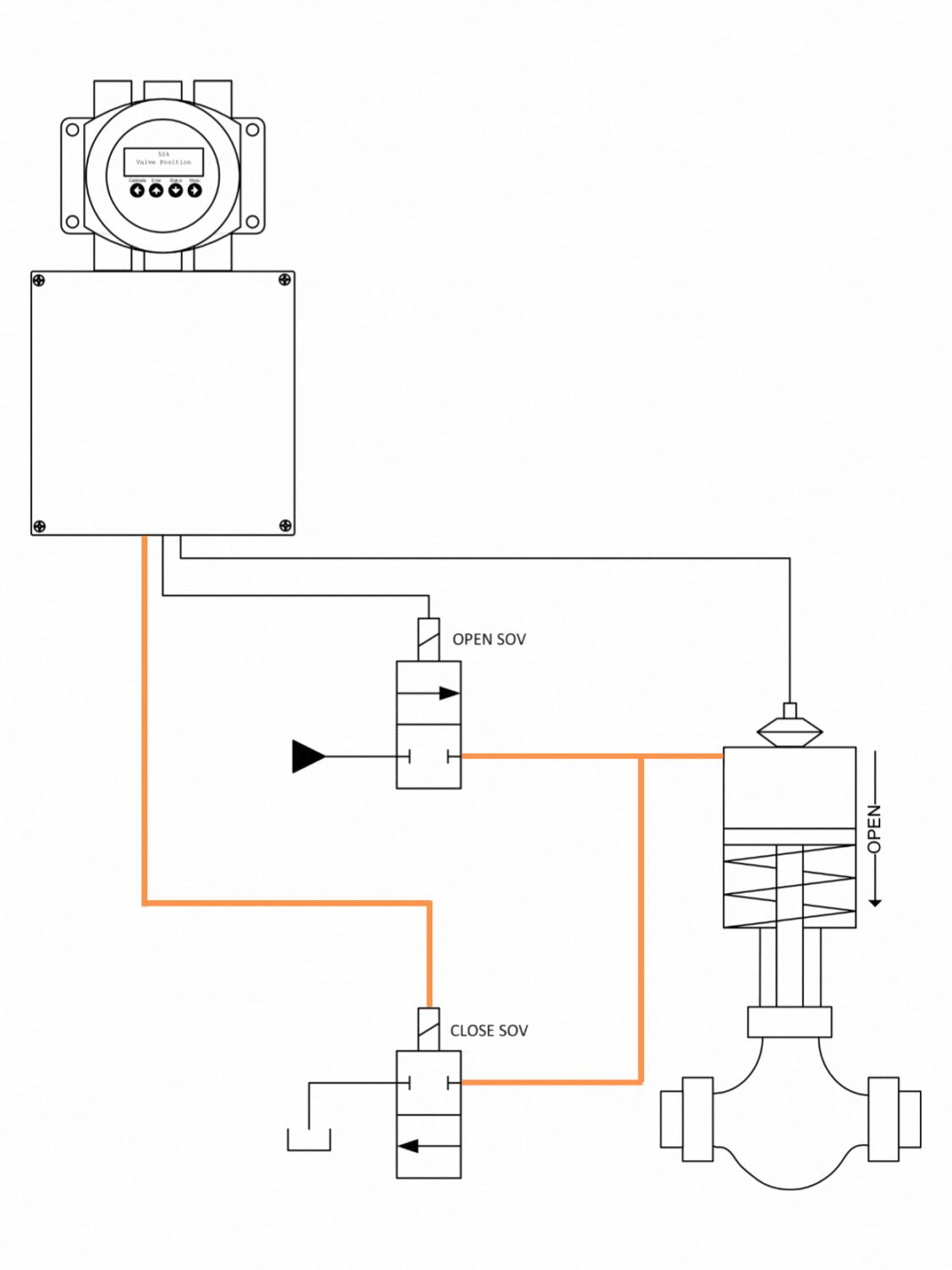

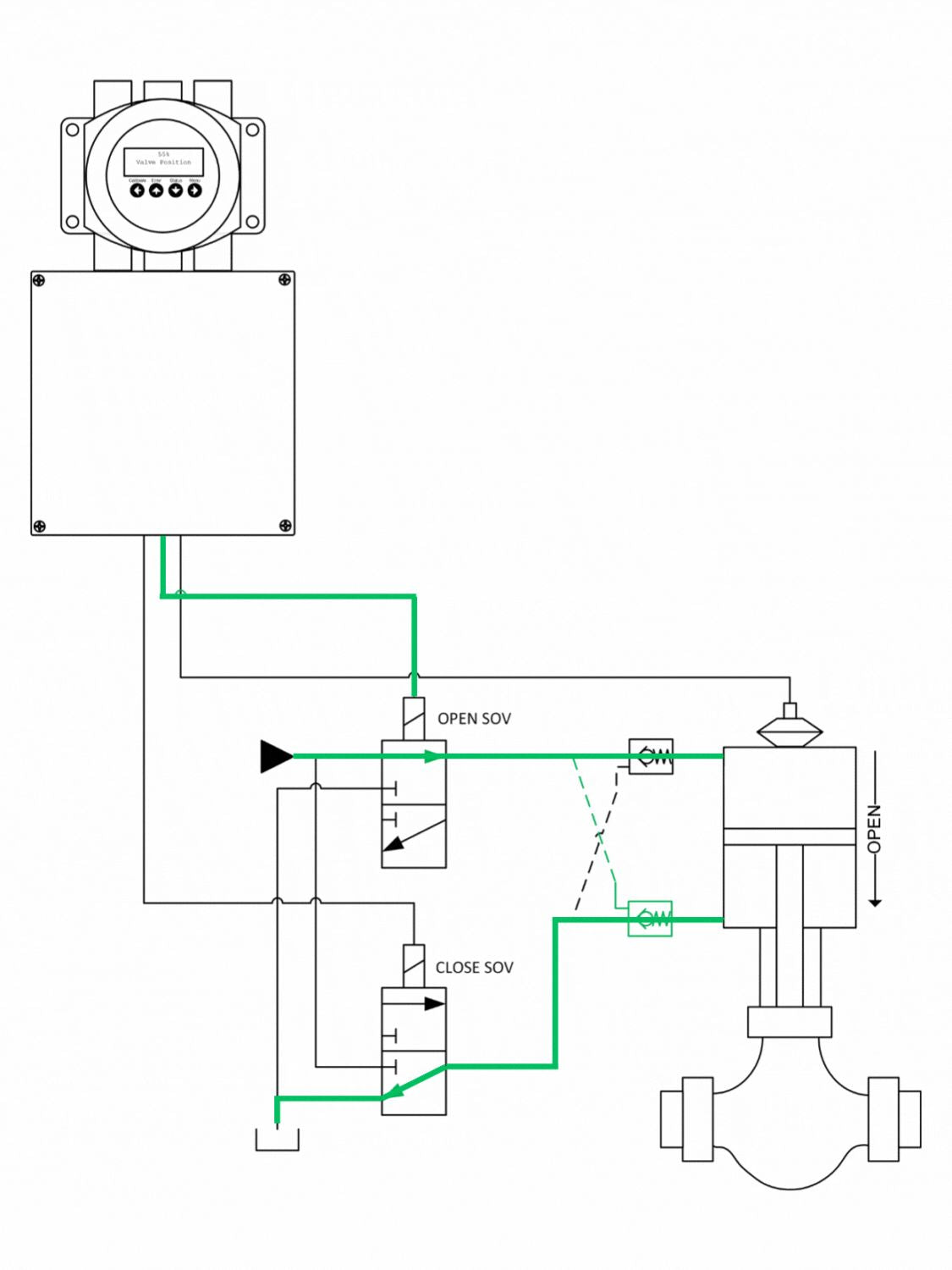

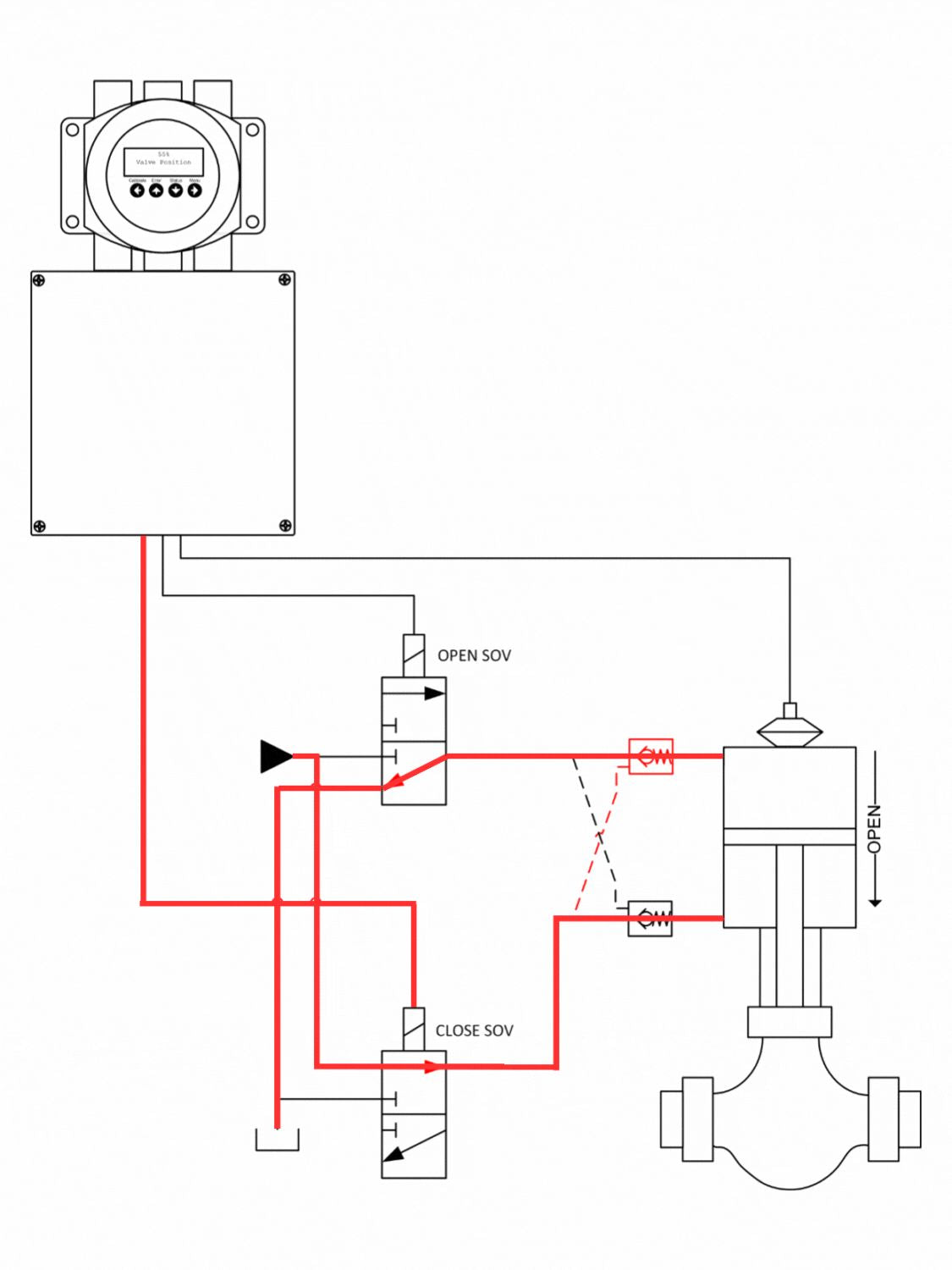

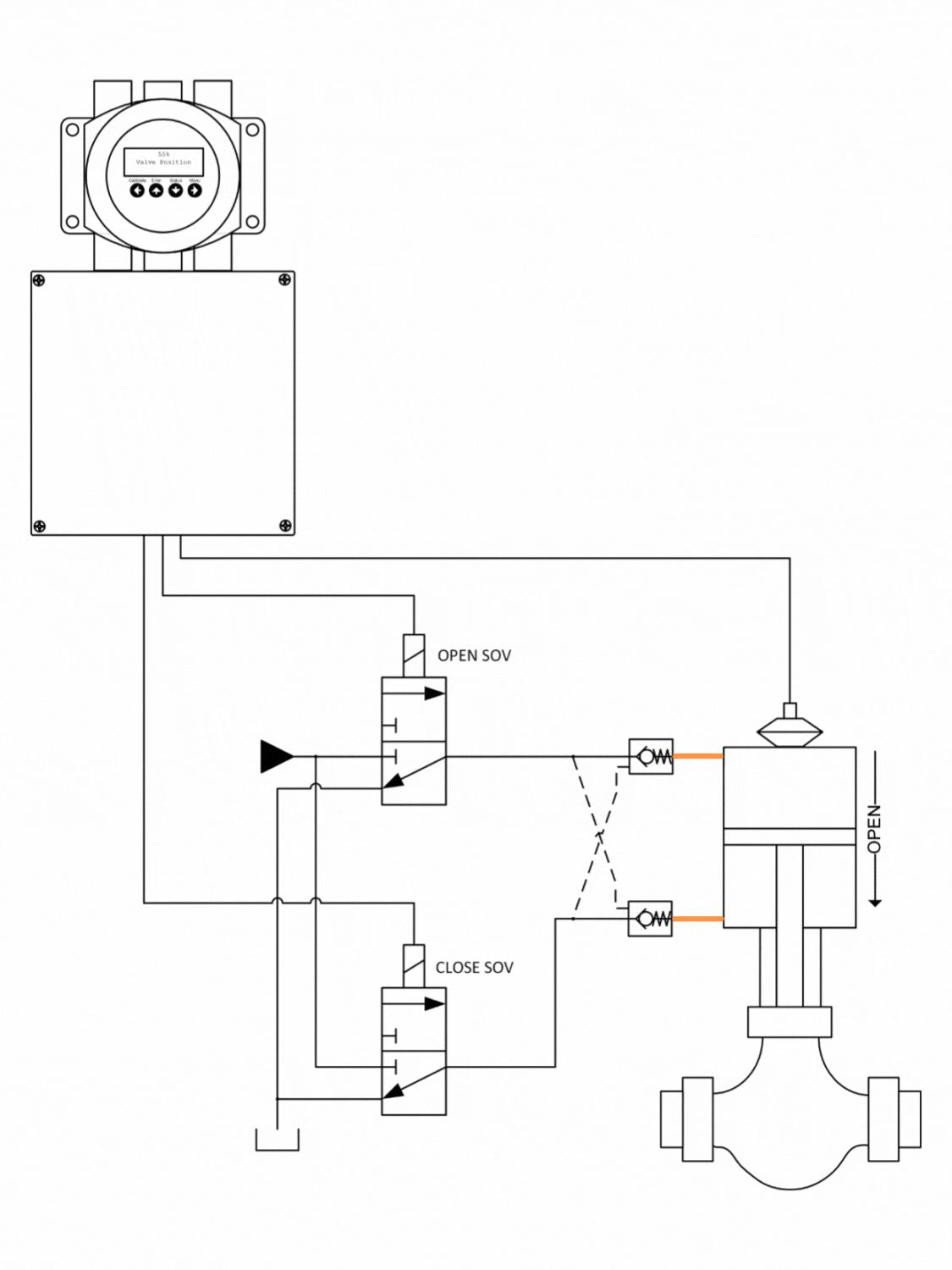

See the schematic below for an example on how the IHP24 can be used with a standard regulator.

The IHP24 comes as standard with the following control and communication:

- 4-20mA Control loop with HART

- 4-20mA Position feedback

It is possible to add the following communication buses:

- Foundation Fieldbus

- Modbus

The IHP24 is powered through a 24VDC power supply.

This power supply also feeds the solenoid valves and the sensors.

The IHP24 uses a signal from the actuator/cylinder to know where it is. The IHP24 accepts the following signal types:

- 4-20mA - 2-wire

- 4-20mA - 4-wire

- 3-wire potentiometer

All our typical designs control two (2) solenoid operated valves, but some of the IHP24 models can control up to 4 solenoid valves. The positioner is also easily adapted to any already existing control systems or other designs.