Electronic Line Breaking System solution

What is an Electronic Line Breaker?

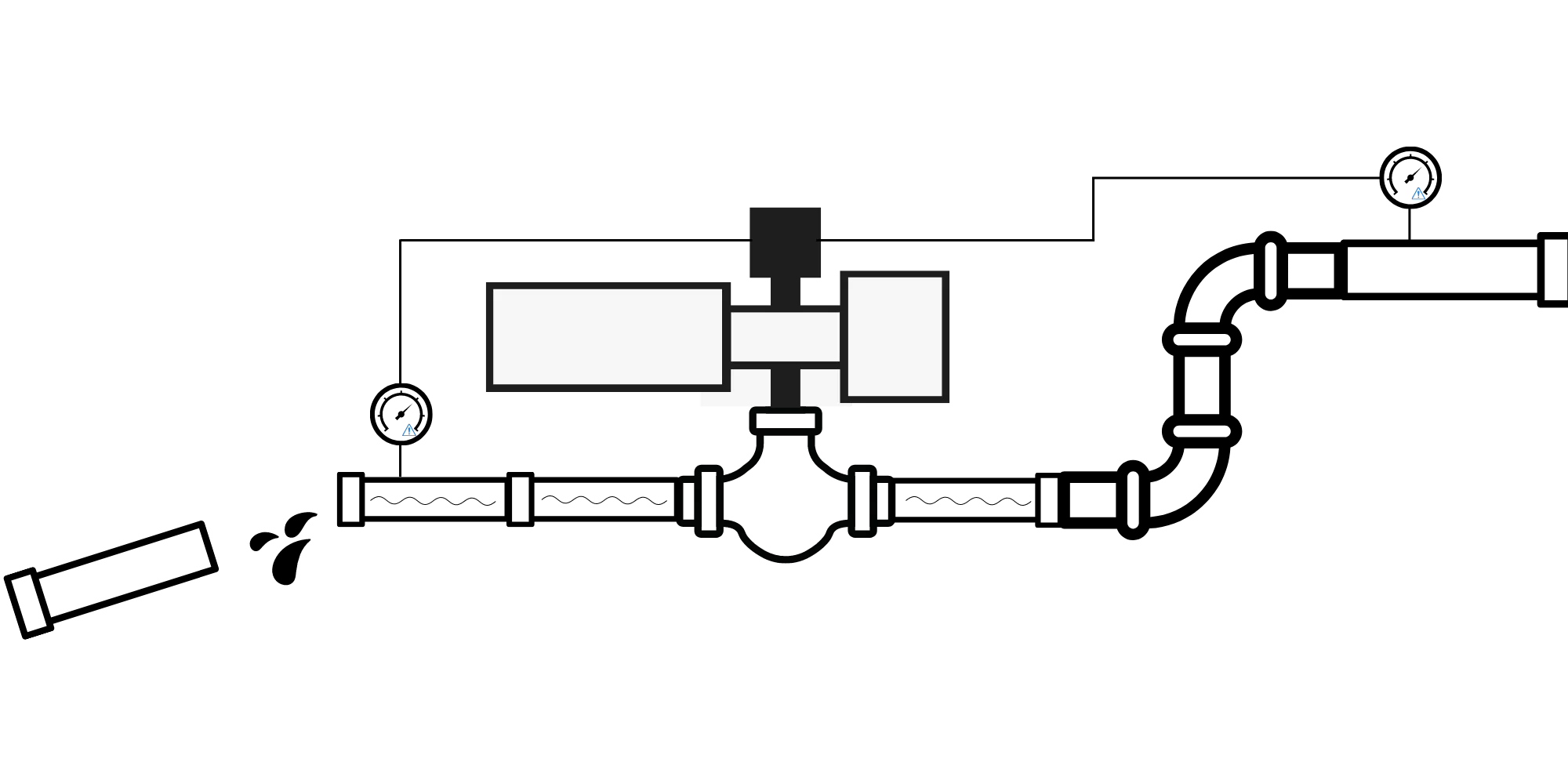

An Electronic Line Breaking System monitor the pipeline pressure and initiates a failsafe procedure when necessary.

Val Controls ILB24 is a cutting-edge line break controller that utilizes the latest expertise in pipeline surveillance to automatically examine the pressure within the pipeline. In the event that the pipeline's pressure is too high or too low, the ILB24 will trigger a failsafe process and successfully obstruct the pipeline's content. The ILB24 controller is adaptable to almost all hydraulic and pneumatic, linear and rotary, double acting or spring return actuators.

Electronic Line Breaking System solution

What is an Electronic Line Breaker?

An Electronic Line Breaking System monitor the pipeline pressure and initiates a failsafe procedure when necessary.

Val Controls ILB24 is a cutting-edge line break controller that utilizes the latest expertise in pipeline surveillance to automatically examine the pressure within the pipeline. In the event that the pipeline's pressure is too high or too low, the ILB24 will trigger a failsafe process and successfully obstruct the pipeline's content. The ILB24 controller is adaptable to almost all hydraulic and pneumatic, linear and rotary, double acting or spring return actuators.

Use case

Challenge

A gas pipeline is passing through a densely populated urban area. It is therefore highly necessary to detect and avoid potential leakages or malfunctions of the pipeline. The company controlling the gas pipeline are looking for a solution which meets the following criteria:

- Minimal spillage in case of a leakage

- Shutdown when a malfunction is detected

- Live data which shows the status of the pipeline

Solution

The gas company chose an Electronic Line Breaking system from Val Controls because it met their demands for the challenge they were facing. With the new Electronic Line Breaking system installed at the valve station they were now able to effectively monitor abnormal pressure levels in the pipeline.

The monitoring is conducted at the valve station and is therefore centralized at one place. In case of a leakage or malfunction of the pipeline the Electronic Line Breaking system will initiate its failsafe system resulting in minimal spillage in case of a

malfunction.

Value

- Environment

The consequences of a gas leakage can be devastating for the local environment. By installing a failsafe system at the pipeline, the leakage will be minimized and further reducing the gas company's overall environmental impact.

- Safety

By installing a failsafe system for the gas pipeline, the overall public safety is increased, and the risk of a potential explosion is reduced significantly. In case of a leakage the Electronic Line Breaking System will shut down the pipeline swiftly and reduce the spillage.

- Reduced operating costs

The need for manual and labor-intensive inspection of the gas pipeline will be reduced. The overall increased safety will reduce the insurance costs for the operating company resulting in overall

reduced operating costs.